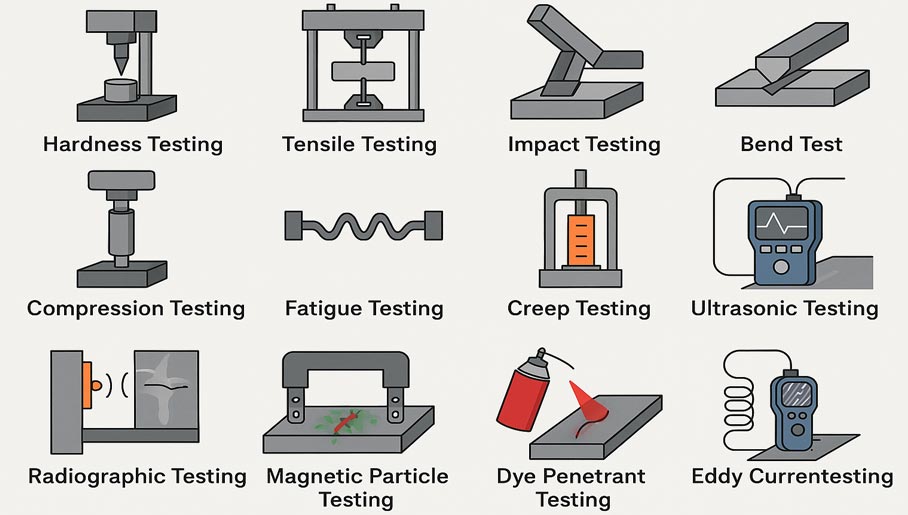

Testing

Hardness Testing

- Tests: – Brinell Hardness Test (BHN), Rockwell Hardness Test (HRB, HRC), Vickers Hardness Test (VHN), Knoop Hardness Test.

- Purpose: – Determines resistance to indentation and wear.

Tensile Testing (UTS - Ultimate Tensile Strength)

- Purpose: – Measures the strength and ductility of a metal under tension.

Impact Testing (Charpy & Izod)

- Purpose: – Evaluates a metal's toughness by measuring energy absorbed during fracture.

- Tests: – Charpy Impact Test, Izod Impact Test.

Bend Test

- Purpose: – Checks ductility and flexibility by bending metal until it cracks.

Compression Testing

- Purpose: – Determines a material's behavior under crushing forces.

Fatigue Testing

- Purpose: – Measures how a metal performs under repeated cyclic loading.

Creep Testing

- Purpose: – Determines how a metal deforms under continuous stress at high temperature.

Ultrasonic Testing (UT)

- Purpose: – Uses high-frequency sound waves to detect internal defects.

Radiographic Testing (X-Ray & Gamma Ray)

- Purpose: – Uses X-rays or gamma rays to detect hidden defects in metals.

Magnetic Particle Testing (MPI)

- Purpose: – Detects surface and near-surface defects in ferromagnetic metals.

Dye Penetrant Testing (DPT)

- Purpose: – Detects surface cracks in non-porous metals using colored dyes.

Eddy Current Testing (ECT)

- Purpose: – Detects surface and sub-surface defects using electromagnetic induction.

Spark Testing

- Purpose: – Identifies metal type by analyzing spark characteristics.

Corrosion Testing (Salt Spray, Pitting, SCC)

- Purpose: – Evaluates metal's resistance to corrosion under different conditions.

Chemical Analysis (Spectroscopy, OES, XRF)

- Purpose: – Determines the exact composition of metal alloys.

At RBD Global Metal Alloy Trading LLC, quality isn’t just a requirement—it’s our promise.

WEAR PLATE STOCKIST & WEAR PART MANUFACTURER SINCE 2010

Get a quote